Our resources include engaging forums, expert opinions, and valuable insights for hand oiler collectors. Our library contains copies of numerous early U.S. patent applications as well as valuable early advertisements and catalogs from some of the major American manufacturers of oilers.

The photo below shows one of our experts (Dennis Lye) at the entrance to the Eagle Manufacturing Company in Wellsburg, West Virginia. He was given a guided tour of the facilities.

Our website emphasizes hand oilers commonly used in a variety of “work” environments. We currently have limited information about oilers used exclusively in households (ex. olive oil, whale oil, etc.) and/or oilers produced in other countries. We welcome information and discussions in these areas. As new information about all types of hand oilers is brought forward by forums and individual collectors it will be incorporated into the website resources.

A common problem with the collection and discussion of individual hand oilers is the interpretation of it’s manufacturer and date of production. Historical documentation about manufacturing companies, various oiler usages through the years and dates of production found in this website will, hopefully, be useful in determining the relative value of individual vintage steel hand oilers.

Terminology

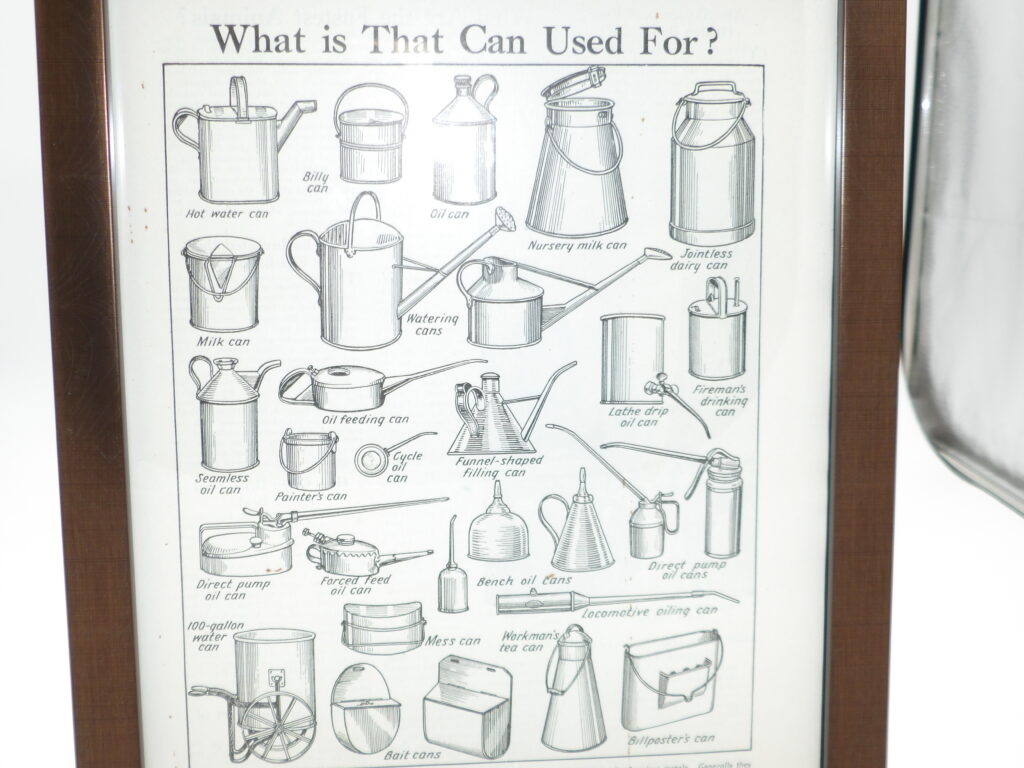

By the early 1900s there were a variety of cans being used in all types of industry as can be seen in this 1933 illustration.

Early oiler cans (prior to the 1870s) were made from copper, tin, brass, pewter, zinc or malleable iron. Steel and tinplate (iron covered with a coating of tin) oiler can production in large numbers began during the 1870s.

For most collectors, the term “oil can” refers to the quart-size containers that contain various distillate products from crude oil. Confusion between the terms “oil can” and “oiler” has existed from the start. A definition of an “Oiler” in the 1906 edition of the Locomotive Dictionary (published by the Railway Gazette: New York, Chicago and London) is given below.

Oiler – a vessel for holding oil, consisting usually of a cylindrical receptacle having a spout or tube to make it possible to reach any bearing or oil hole.

At Oiler Alley, we use the term “hand oiler” for all the various types of containers that can be carried by hand and used to transfer oil products to a particular location in a work area. It is convenient to divide hand oilers into three groups according to their size (pocket oilers, bench oilers and railroad oilers).

Pocket oiler – a small hand oiler that can be easily transported and which contains only a few ounces of oil. These hand oilers are often referred to by the most common function performed (sewing machine oiler, fishing reel oiler, bicycle oiler, rifle oiler, etc.).

Bench oiler – an intermediate refillable container (usually called “body” or “can”) which contains volumes from many ounces to pint to quart size. A bench oiler with no movable parts has many common names (dimple oiler. pressure oiler, pinch oiler, push oiler, thumb oiler, bottom oiler, clicker oiler, etc.).

A bench oiler consisting of a refillable container that has integrated moving parts for the delivery of a steady, temporary stream of liquid in any direction is referred to as “pump oiler”.

Railroad oiler – this hand oiler has a large refillable container that may or may not have integrated parts for delivery of liquids. These oilers are used for larger machinery such as engines. These hand oilers are often referred to by the most common function performed (railroad oiler, automobile oiler, tallow pot, etc.).

Documentation

Historical documentation about manufacturing companies, various oiler usages through the years and dates of oiler production are helpful in determining the value of vintage steel hand oilers.

Here is an example. This photo was taken of an actress and an array of hand oilers. The photo was dated May 24, 1943, and the description was given as follows:

“For many years, “Inner Sanctum” listeners have been writing in to request that the program’s famous creaking door be treated to a good lubrication job. Lately, fans have been sending oil cans to speed the process. Lovely Elspeth Eric, a BLUE Network actress heard on the show, surveys the latest mail batch.”

The type, shape and size of hand oilers commonly produced in the 1940s can be assumed from this type of documentation.

Here at Oiler Alley, we are interested in documentation that collectors have acquired over the years. Sharing of this type of information can assist in associating certain hand oilers with production dates. Please send us your examples of documentation so that it can be shared with other interested collectors. Send your examples to oileralley2024@gmail.com along with your name and location.

Timeline

A Timeline of Major American Hand Oiler Manufacturing Companies

Timelines are often presented to generate discussion among collector communities about the documentation supporting the relative age and monetary value of specific items. Every timeline is a “work in progress” and can be amended as the collector community uncovers new evidence/documentation.

The dates given in this timeline represent the start of hand oiler production by each of the manufacturers listed. Many of these manufacturing companies produced oilers over an extensive period of years.

Please contact us at oileralley2024@gmail.com if you have questions or suggestions about existing/new documentation and dates of production of specific items.

1857 – Dover Stamping Company, Dover, NH

1861 – The Consolidated Fruit Jar Company, New Brunswick, NJ

1864 – Hammer and Company, Branford, CT

1864 – P. Wall Manufacturing and Supply Company oilers, Pittsburgh, PA

1865 – Dover Stamping and Manufacturing oilers, Cambridge, MA

1866 – Olmsted Spring-top oilers, Stamford, CT

1869 – Singer Sewing Machine oilers, New York, NY

1875 – Chace Patent oilers, New York, NY

1877 – Broughton oilers, New York, NY

1880 – F. Draper and Company oilers, Cambridge, MA

1880 – Asbury Paine Mfg. Co. glass oilers, Philadelphia, PA

1882 – H.S.B. Manufacturing oilers, Chicago, IL

1883 – Paragon oilers, Boston, MA

1884 – Hammer Company oilers, Branford, CT

1887 – Consolidated Fruit Jar Company oilers, New Brunswick, NJ

1891 – H.A. Williams Manufacturing oilers, Boston, MA

1893 – Wilmot and Hobbs Manufacturing oilers, Bridgeport, CT

1899 –American Tube and Stamping Company oilers, Bridgeport, CT

1899 – GEM Manufacturing oilers. Pittsburgh, PA

1902 – Johnson Manufacturing oilers, Urbana, OH

1905 – Hero Manufacturing oilers, Philadelphia, PA

1905 – Noera Manufacturing oilers, Waterbury, CT

1907 – Maple City Manufacturing oilers, Monmouth, IL

1907 – Eagle Glass and Manufacturing oilers, Wellsburg, WV

1920 – Lidseen Manufacturing oilers, Chicago, IL

1920 – Dutton-Lainson oilers, Hastings, NE

1927 – Plews Manufacturing oilers, Minneapolis, MN

Numerous small manufacturers have not been included in this timeline.

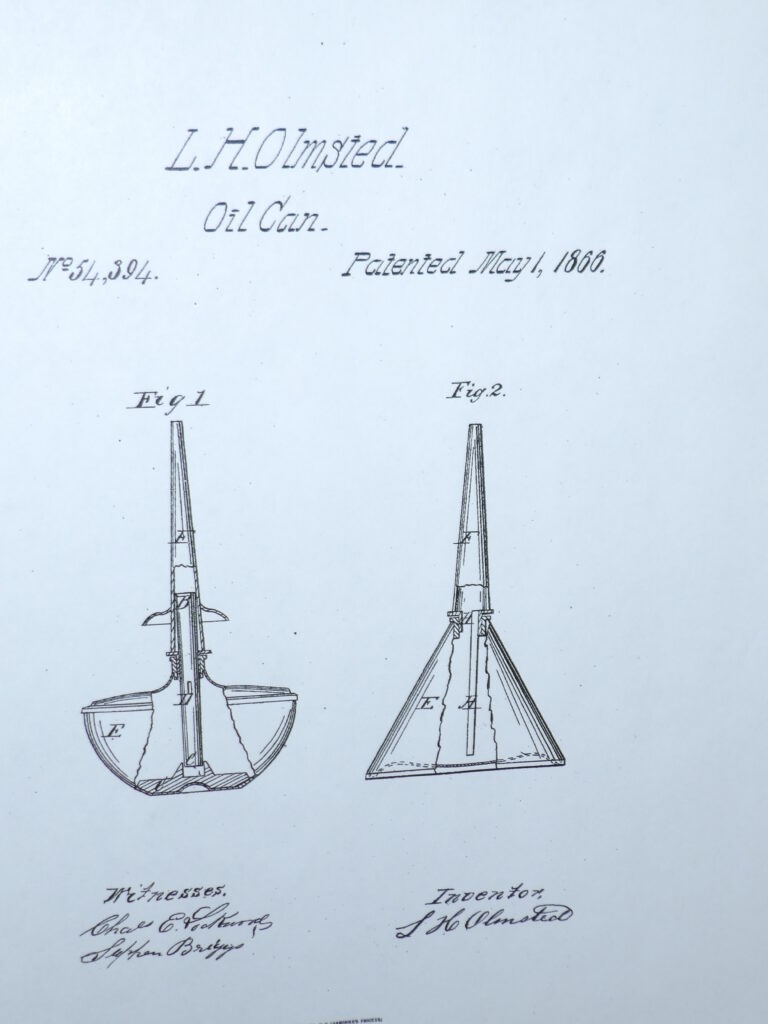

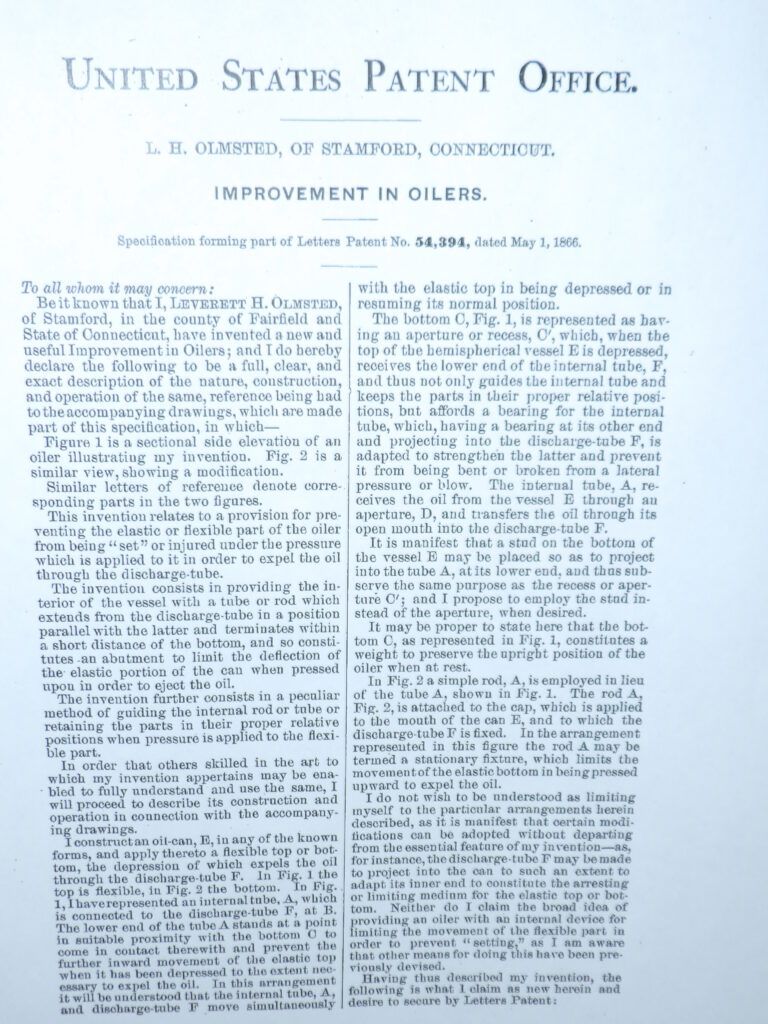

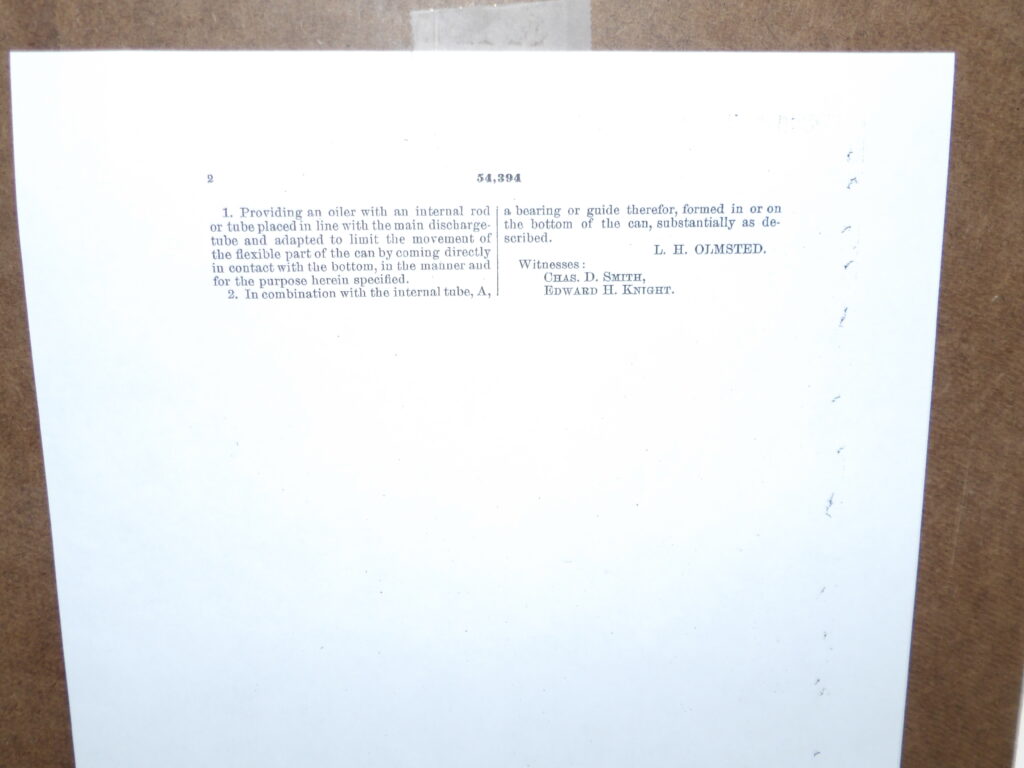

We have selected the production of Olmsted spring-top oilers in 1866 as an example of the types of documentation useful for incorporation into the timeline and in determination of probable production dates (how old a specific hand oiler might be).

Below are photos of the May 1, 1866 patent taken out by L. H. Olmsted for this oiler.

Of course, the best documentation are images of the actual vintage hand oilers (shown in the next two images) for the Figure one oilers in the patent application. These three Olmsted oilers are over 130 years old and available for purchase here in Oiler Alley.

Oiler Alley has similar documentation for many vintage hand oilers in our library as well as many of the actual hand oilers available for the collector community.

Lubricants used in vintage American hand oilers

One of the earliest lubricants used in small pocket oilers was discovered by British soldiers during their campaigns in India. They found a heavy viscous solution bubbling to the surface in natural oil springs of the Rangoon region of India. This “rangoon” oil was used to prevent rust in arms in hot, steamy conditions. It was a tenacious oil with a very slow evaporation rate.

Before commercial distillation of oil, many of the early lubricants were thick, viscous fluids that were difficult to deliver by metal hand oilers. Often, the metal oilers holding these early lubricants had to be heated so the lubricants within could be delivered.

Early refineries used simple distillation towers to separate crude oil into black strap oil, kerosene, light lubricating oil and heavy lubricating oil. Black strap oil had a consistency of present day “grease”. The residue at the bottom of the distillation towers could be used to lubricate hot steam cylinders and was known as “cylinder stock”.

In the late 1800s, American soldiers used an oil called “cosmoline” obtained from residues of oil distillation to lubricate rifles and carbines. It consisted of a mixture of paraffins, a kind of petroleum jelly.

One example of a lubricating fluid in use in the early 1900s is given below. This description was taken from “Machinery’s Shop Receipts and Formulas” published in 1911 by The Industrial Press, New York.

BEARING LUBRICANT

Melt 1-pound solid paraffin and add 2 ounces of litharge, dissolved isinglass and sulphur. Then further add 2 pounds of fine plumbago and mix thoroughly.

Litharge is one of the natural mineral forms of lead oxide (PbO).

Isinglass was a substance obtained from the dried bladder of fish. It is a form of collagen.

Plumbago was a term often used for graphite.

Household Oilers

Among the first oilers to become common in American households were those used for sewing machines. Among the first companies to build sewing machines was the I. M. Singer and Company, established in New York in 1851 by Isaac Merritt Singer. The first sewing machines (1869) were commercial machines used in the garment industry. A patent for a sewing machine “oil can holder” was issued in 1869 (November 2; 96,527). In 1889, Singer designed a machine for use in the home. By 1905, electrical sewing machines were commonplace in households. Because these machines had many moving parts, an oiler was a necessity for proper maintenance.

Collectors of vintage Singer sewing machine oilers realize the diversity of oilers with “Singer” embossed on the cans. A variety of companies provided oilers to Singer over the long history of this company.

Allen B. Wilson founded the Wheeler and Wilson Manufacturing Company in Watertown, Connecticut in 1853, for the manufacture of sewing machines. By the 1860s, this company was the largest sewing machine manufacturer in the world. A 1865 advertisement offered a variety of attachments, one of which was an oiler holder. Early oilers offered by Wheeler and Wison were designed by S. R. Wilmot (patent 2594; February 26, 1867). The company was acquired by the Singer Corporation in 1905.

Many of these early metal sewing machine oilers are collectible.